If you adhere to the old saying, “Cooking is an art and baking is a science.” then you understand that baking a cake is not the time for artistic improvisation! Baking a cake requires careful observations of ingredients, adhering to the outlined method, and implementing the recommended tools, all while following a precise recipe. And guess what, the cake pans you use are an important part of that cake baking equation!

The cake pan has the potential to make or break your cake. A good cake pan will distribute heat evenly, helping the cake to rise uniformly. A cake pan that does not conduct heat well, will leave you with an uneven bake, cooking the edges before the middle. When the edges are set, the middle of the cake will continue to rise, resulting in a domed cake. Boo.

So, we have some suggestions to help you get started with the right pan. If you’re looking to step up your cake baking, getting the right pan will make all the difference.

Types of Cake Pans

Aluminum – This is the most commonly used metal for cake pans. It has superior abilities in conducting heat, producing a cake that is evenly risen. It is also an inexpensive metal, making it a cost-effective option for bakers needing a large amount of cake pans. Lightweight aluminum cake pans make beautiful cakes.

The only concern for using aluminum pans is their tendency to corrode after exposure to acidic foods. This is most common with citrus fruits, tomatoes, and cocoa powders. There is a risk of the acid breaking down the aluminum leading to bits of aluminum leaching from the pan, ending up in your food. You can prevent this breakdown by baking acidic foods in other pans.

We do not recommend this type of pan. While they bake nicely, there are better non-reactive options available.

Anodized Aluminum – This is the pan for serious bakers. The magic of this metal is that it has the ideal baking abilities of aluminum, but with an anodized finish to prevent the corrosion that occurs with natural aluminum.

Anodization is a process in which the metal is electrochemically treated, increasing the thickness of the oxidized layer of aluminum. This layer is not painted or poured on the pan, so it can’t chip off. It is fully integrated with the aluminum underneath. This strengthened layer is nonreactive, scratch resistant, and not affected by acidic ingredients.

Pans made from anodized aluminum solve the problems presented by natural aluminum pans. They bake beautiful cakes while being nonreactive!

Buy anodized aluminum pans if you are baking a lot of cakes. We fully recommend Fat Daddio’s anodized aluminum pans. We bake hundreds of cakes for our hands-on cake classes every month. These are the pans we use and we couldn’t love them more!

Aluminized Steel – These pans capitalize on the strength of steel, making pans that are sturdy, resisting dents and scratches. But, steel alone is a terrible conductor of heat, so it is dipped in an aluminum alloy, combining the desired attributes of both metals. The resulting cake pan conducts heat evenly, while being sturdy and strong.

Most aluminized steel pans are further coated by silicone or a ceramic coating to enhance the non-stick abilities of the pan. These coatings are sturdier than most non-stick coatings, making these pans a better investment.

The trade off is the price. These pans tend to be more expensive, but they are worth buying if you hope to keep them for many years to come.

We love the aluminized steel pans from Chicago Metallic. They are sturdy enough to last a lifetime!

Carbon Steel – Cake pans made from carbon steel are very inexpensive. They are usually thin sheets of metal, coated with a non-stick coating. Often found at grocery stores, they are often stackable pans. This is great for storage! But, not so great for a beautifully baked cake. The resulting edge is slanted like the edge of the pan. This presents difficulty for stacking and decorating a straight edge.

These pans are usually coated in a standard nonstick coating. They are dark in color, which affects the cake. The dark color absorbs heat instead of reflecting it, causing the edges of the cake to bake quickly too quickly. The center of the cake will still be liquid and will continue to rise, resulting in a domed cake. This is makes stacking cakes very tricky!

We do not recommend carbon steel pans.

Nonstick Coatings – Cakes pans are available in a wide variety of finishes. The advantage of nonstick pans is the easy release and clean up of the pan. The most common nonstick coatings are applied by dipping the pan into a dark-colored coating. This finish is susceptible to scraping and flaking from the pan, revealing the metal underneath. The exposed metal pan is then likely to rust and corrode.

You can prevent this flaking of the coating by hand-washing your nonstick cake pans, while also avoiding metal utensils. These extra measures will prolong the life of your cake pans.

We suggest the nonstick cake pans from Chicago Metallic.

Another option is a silicone coating. This nonstick coating is free from toxic chemicals associated with other nonstick coatings (PTFE, PFOA, & BPA free). Our favorite silicone coated cake pans are made by USA Pans.

Glass & Silicone Pans – We do not recommend using glass or silicone cake pans. They present many difficulties for beautifully baked cakes. Silicone is a terrible conductor of heat, requiring a long amount of time to heat the cake. The result is a cake with an underdeveloped crust. The cakes are also hard to remove from the pan.

Glass pans also take a long time to heat. But when they do reach the desired temp, they hold their heat for a long time. So, when your cake is removed from the oven, it’s still going to keep baking. Not so awesome. The resulting crust is undesirable. Glass pans are also susceptible to cracking and breaking, as they struggle to adjust to changes in temperature. They are not practical in any commercial kitchen, but are also poor performers in home kitchens.

Size of Cake Pan

The size of cake pan you use will depend on the style of cake you are wanting to make.

The classic, most traditionally used cake pan is a 9″x2″ round cake pan. This is the cake your mother used to bake for your birthday. Haha. Most recipes will adequately fill two 9″ cake pans. If the recipe does not specify a size, you’re probably safe to assume it will fit beautifully in two 9″ cake pans.

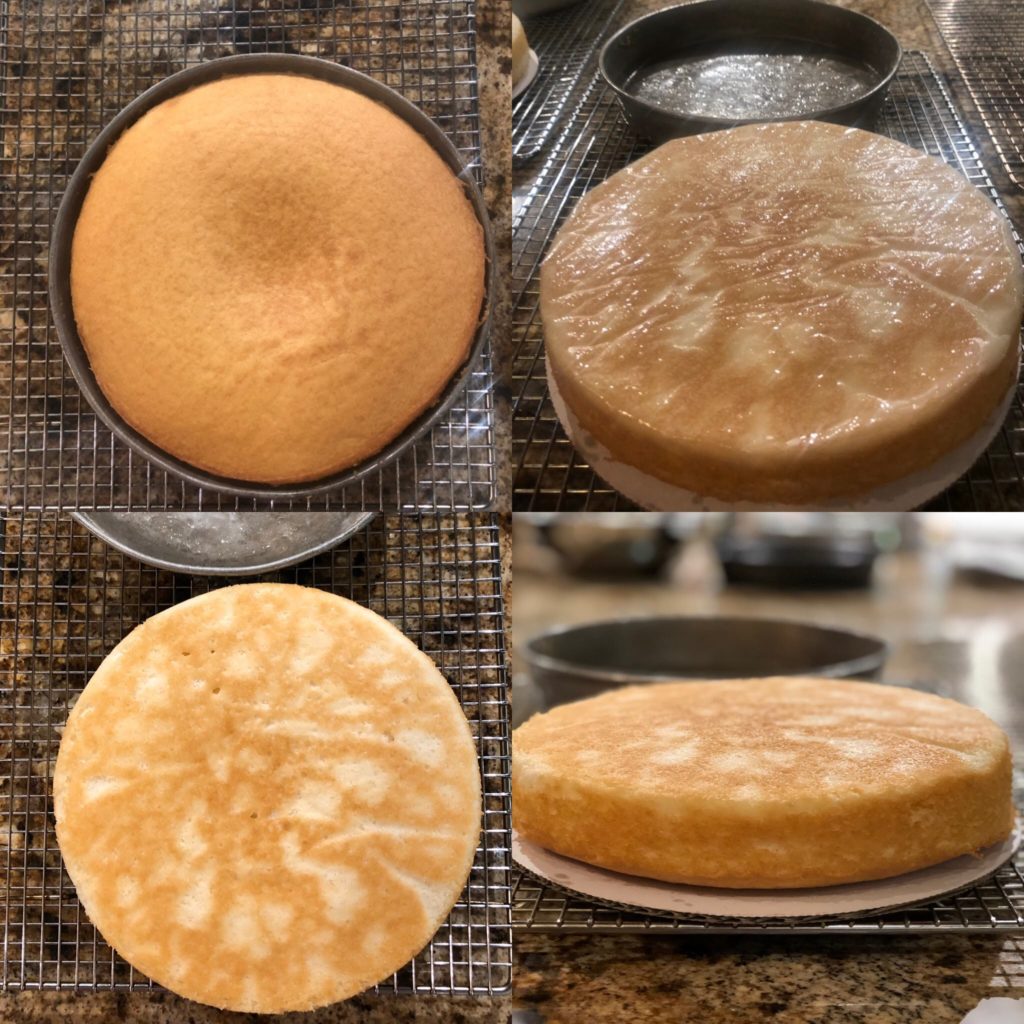

But, the current trend is to bake 8″ round cakes. With this style, 3 layers of 8″ round cakes are stacked together to make a taller and more slender cake. This style is achieved with 8″x2″ round cake pans.

Another popular option is a 6″x2″ cake pan for a more slender stack of cakes. This is the size we use in our hands-on cake classes with Cake by Courtney. The resulting cake is very easy to handle and decorate, making this a great option for beginning decorators.

We love to bake in the 2″ deep pans, as we feel they bake very nicely and evenly. But, another option is to bake in 3″ deep or 4″ deep pans, making a taller cake. Then, the baker will slice the cake layer in half, allowing for more layers of frosting and filling in between. The depth you choose totally depends on your preference.

If you are just starting with baking, we suggest buying 3 – 8″x2″ cake pans. You will be happy with their performance and versatility. Get the Fat Daddio’s pans if you are looking for a great pan to reliably bake all your cakes. Invest in the Chicago Metallic pans if you need something more sturdy. You will have great success with those pans.